- Joined

- Nov 29, 2005

- Posts

- 4,275

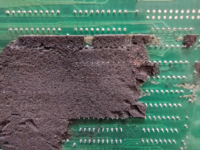

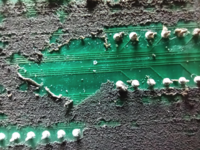

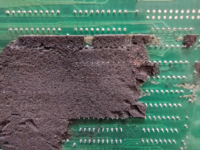

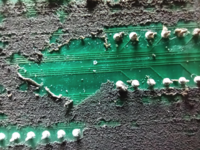

Hey folks, when the fish paper and foam on the under side of the top board hardens, it will start corroding traces under it.

The 4-slot sent to me had a complaint of graphic corruption on slot 4. Here's the corroded via that was the cause of the complaint:

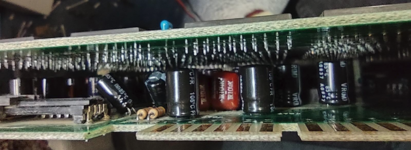

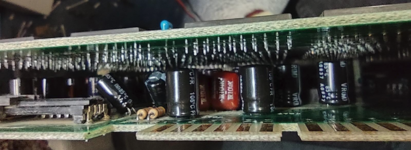

BUT... the customer's board had a bad cap kit job so they would be rubbing up against the pins of the chips above them. This meant I had to un-eff the board as part of the repair.

Now with the caps installed properly...

The top board fits without any interference from below!

And if you were wondering about the repair for slot four... It was a simple Kynar patch to the via on the top side of the PCB.

The 4-slot sent to me had a complaint of graphic corruption on slot 4. Here's the corroded via that was the cause of the complaint:

BUT... the customer's board had a bad cap kit job so they would be rubbing up against the pins of the chips above them. This meant I had to un-eff the board as part of the repair.

Now with the caps installed properly...

The top board fits without any interference from below!

And if you were wondering about the repair for slot four... It was a simple Kynar patch to the via on the top side of the PCB.